1. Order code: SHC5540

2. Description: 4 x Capacity 55 Ton, 1000 mm Stroke, SyncHoist Cylinder W/Sensors. / Hệ thống Nâng Đồng Bộ (Synchronous Hoisting) với 4 bộ kích thủy lực 55 Tấn, hành trình 1000mm

3. Technical Specifications

| Specification | Value |

|---|

| Hexagon Size S (mm) | 60 |

| Hexagon Size S (in) | 2 3/8 |

| Nose Radius H (mm) | 51.0 |

| Weight (kg) | 8.1 |

4. General information:

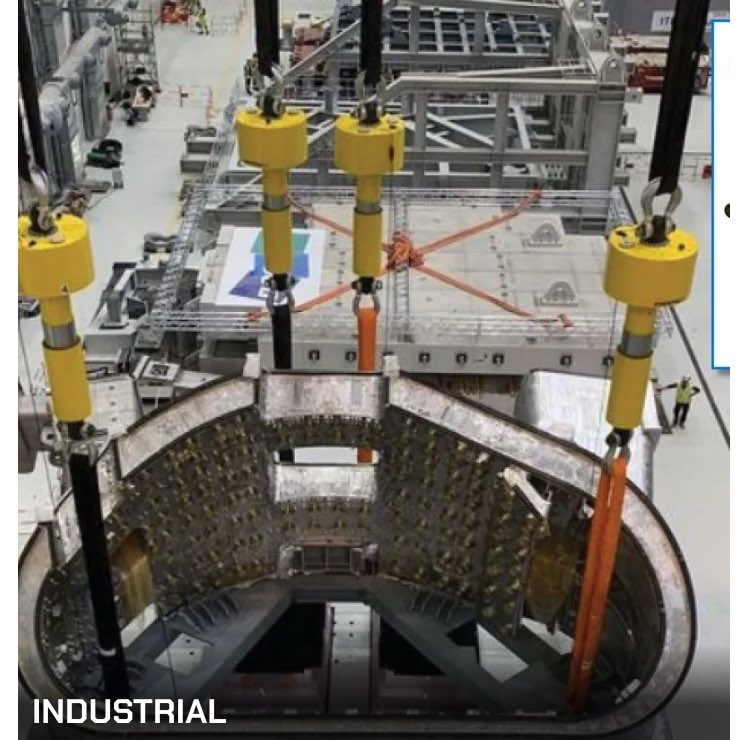

The SHC-Series SyncHoist cylinder is a below-the-hook sling adjuster (hydraulic turnbuckle). It is mounted directly in-line with the rigging and provides an operator the freedom to precisely monitor and adjust each lifting point independently. The use of integrated stroke sensors and pressure transducers at each lifting point allow for position and load feedback at the operator control station. Optional PLC controls deliver operator safety while the intelligent hydraulics monitor and guide the compact hydraulic cylinders.

Accurate hoisting and load positioning enhance the capability of a single crane. With the use of a single crane, the load can be precisely maneuvered in a vertical and horizontal plane. Utilizing a single crane reduces risk and cost, and vastly improves operating speed and worker safety. A single crane also reduces the risk of damage from oscillations of wire rope due to sudden crane starts/stops.

The synchronous hoist system can be used for pre-programmed positioning, tilting, aligning and high precision horizontal and vertical load positioning.

Features

- High precision horizontal and vertical load positioning

- High precision load maneuvering using one crane

- Reduces the risk of damage from oscillations of wire rope due to crane jogging and sudden starts/stops

- Vastly improving worker safety, operating speed and control

- PLC-controlled hydraulics turn lifting into high accuracy hoisting and load positioning system

- Double-acting push/pull cylinders with load holding valves for added safety

- Increased efficiency compared to conventional load positioning methods

- Complete system tested in compliance with European lifting directive and BTH-1 safety requirements

- Optional automatic control

- Load and stroke monitoring, and stroke control

- PLC-control and touch screen

- Solenoid valves with pendant

- Pre-programmable motions and data recording

- System warnings for:

- maximum cylinder load control setting

- stroke and position control

- thermal motor protection

- oil level and filter indicator

5. Synchronous Hoisting

Enerpac SyncHoist is a unique crane product for below-the-hook positioning of heavy loads that require precision placement. The SyncHoist system may reduce the number of cranes needed and reduce the costs of multiple picks.

Functions

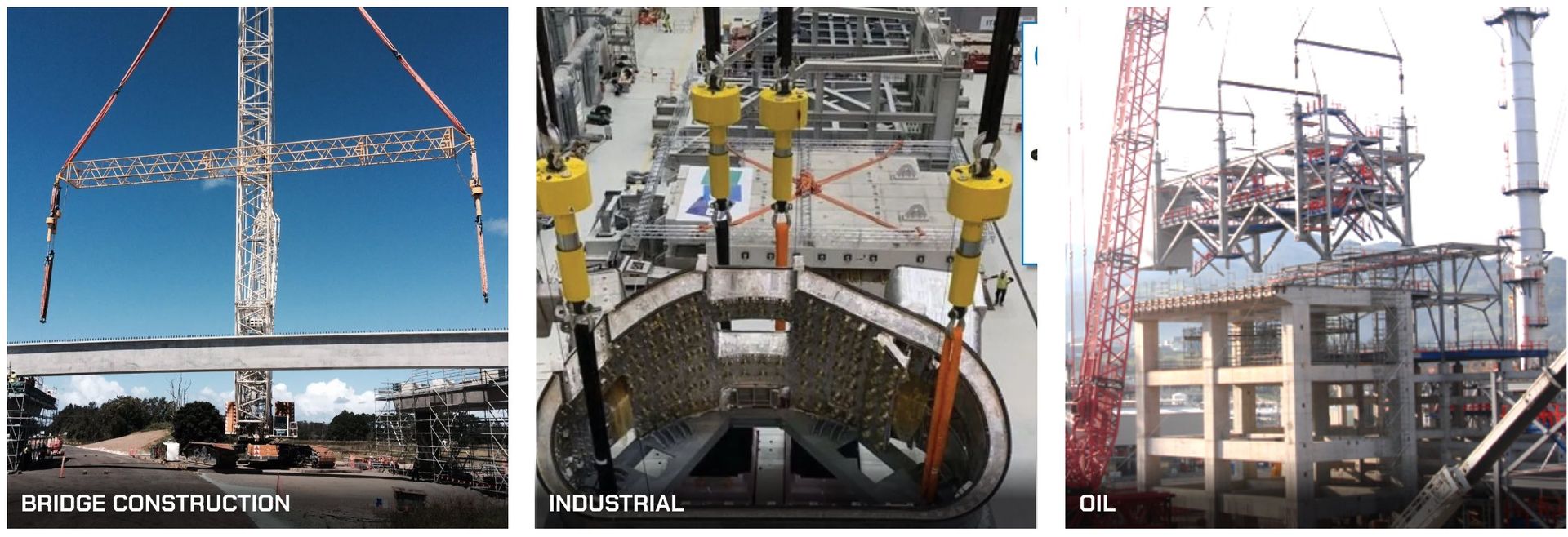

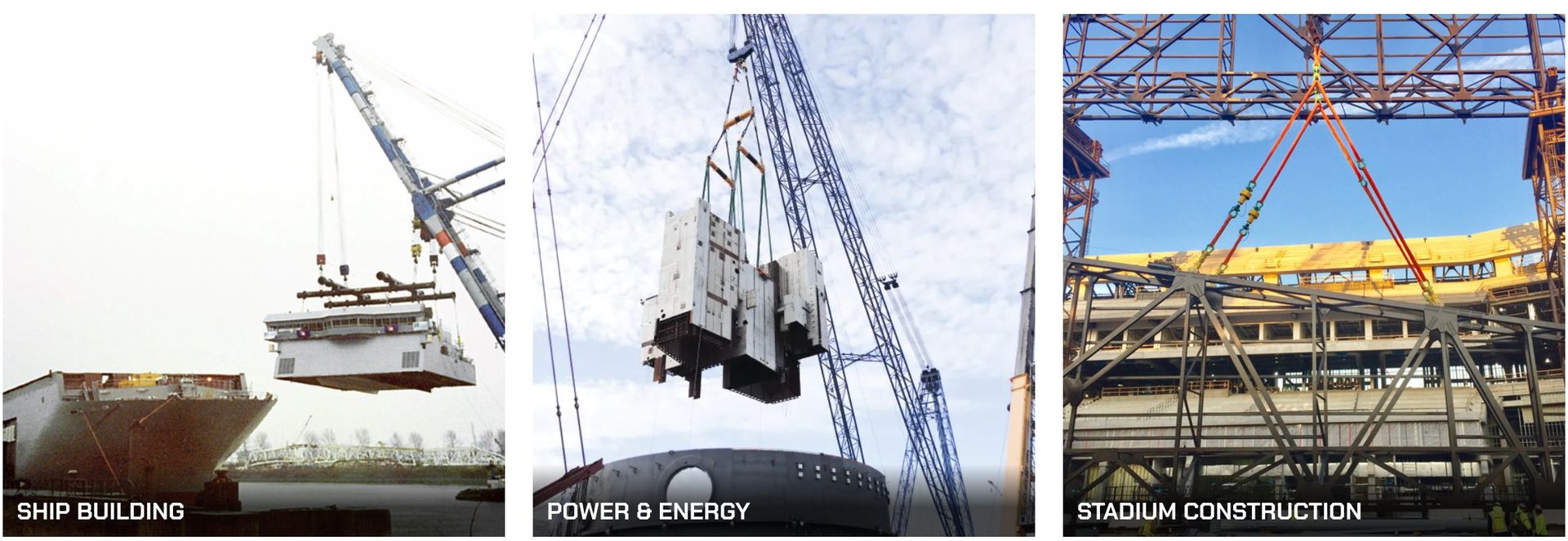

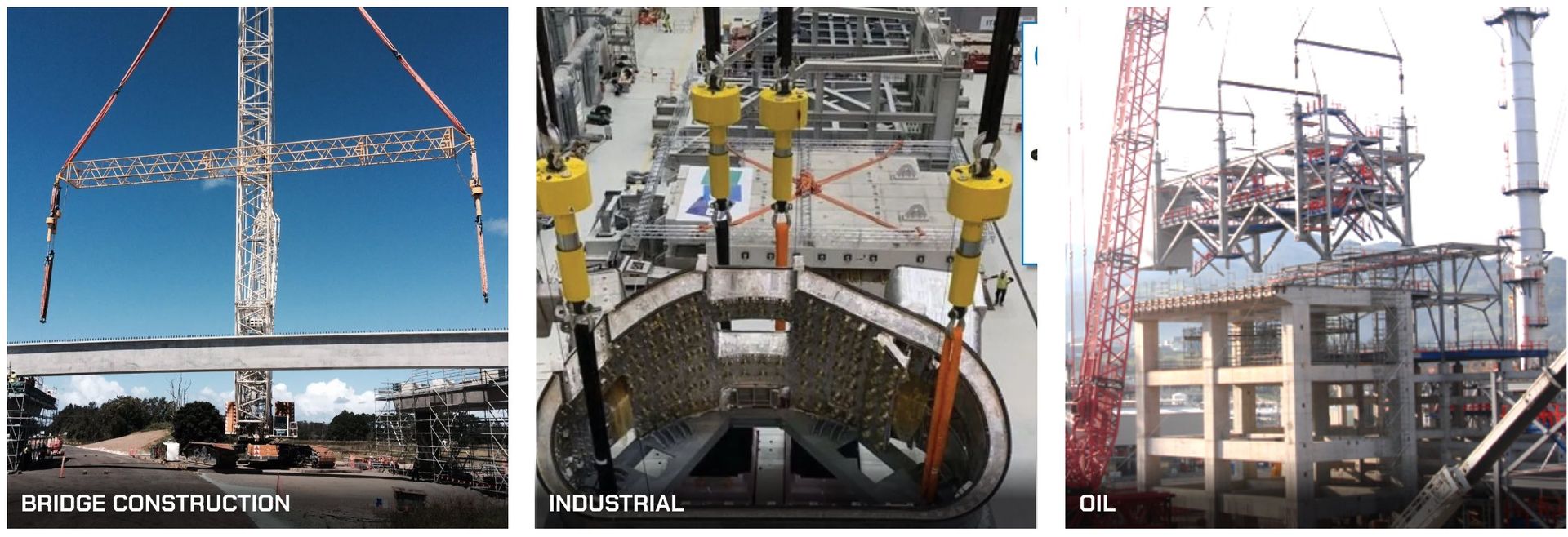

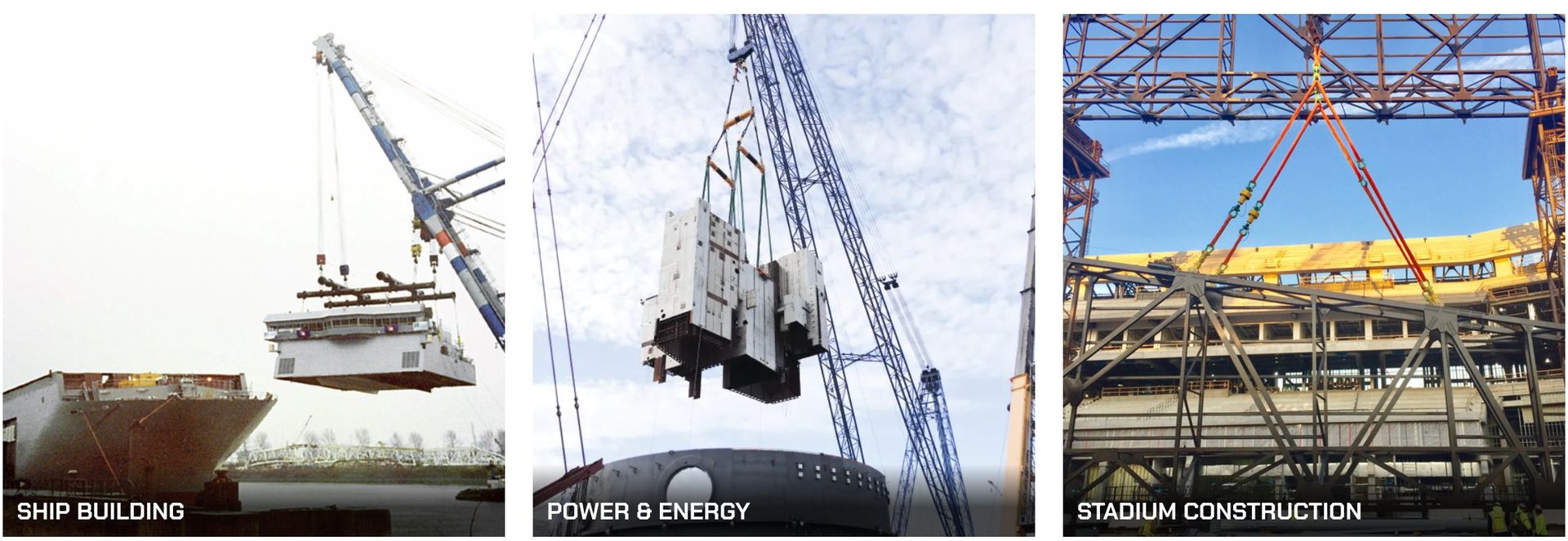

Applications

-

Positioning of rotor, stator and propeller blades of wind turbines

-

Positioning of roof sections, concrete elements, steel structures

-

Positioning of turbines, transformers, fuel rods

-

Precise machinery loading, mill rod changes, bearing changes

-

Precise positioning of pipe lines, blow out valves

-

Positioning and aligning of ship segments prior to assembly.

5 / Nâng Đồng Bộ (Synchronous Hoisting)

Enerpac SyncHoist là một sản phẩm cẩu độc đáo dùng để định vị tải trọng nặng bên dưới móc cẩu, yêu cầu độ chính xác cao khi đặt vị trí. Hệ thống SyncHoist có thể giúp giảm số lượng cẩu cần sử dụng và tiết kiệm chi phí cho các lần nâng hạ nhiều điểm.

Chức năng

Ứng dụng

-

Định vị rotor, stator và cánh quạt của tuabin gió

-

Định vị các khối mái, cấu kiện bê tông, kết cấu thép

-

Định vị tuabin, máy biến áp, thanh nhiên liệu

-

Nâng thiết bị chính xác, thay trục cán, thay vòng bi

-

Định vị chính xác các đường ống, van xả áp (blow out valve)

-

Định vị và căn chỉnh các đoạn thân tàu trước khi lắp ráp

6. Một số video mô tả nguyên lý và hoạt động:

![]() and then Add to Home Screen.

and then Add to Home Screen.